Superior Metal work Your Partner in Custom Metal Fabrication Services

Welcome to Superior Metal work your trusted partner for top-tier custom metal fabrication services tailored to your unique needs. With

From the towering skyscrapers that define city skylines to the complex machinery powering our everyday lives metal fabrication is used in countless innovations across diverse industries.

The significance of mastering metal fabrication techniques, like cutting and welding services cannot be overstated. Imagine making a car without knowing how to weld its frame, building machines without cutting metal precisely or putting up buildings without shaping metals the right way. It’s like trying to solve a puzzle without having all the pieces—it’s really hard and might not even work out in the end.

So, whether you’re a DIY enthusiast, a budding fabricator, or just someone eager to know how your favorite things are made, this guide is your pass to understanding the nuts and bolts (literally!) of metal fabrication. Get ready to explore, learn, and maybe even get inspired to create your own metal masterpieces!

When it comes to cutting metal there are different ways to get the job done:

Laser cutting involves using a high-powered laser beam to slice through metal with extreme precision. This method is highly efficient and suitable for intricate designs due to its fine accuracy.

Plasma cutting employs a plasma torch to cut through conductive metals by melting them with a jet of hot plasma. Simply put, this method uses a special torch that heats up and melts metal, kind of like a super-hot flame. It’s great for cutting through thicker pieces quickly.

Water jet cutting utilizes a high-pressure stream of water mixed with an abrasive substance, such as sand, to cut through metals and various other materials. It’s prized for its ability to handle diverse materials without causing heat-affected zones or altering material properties.

This involves mechanically cutting through metals using traditional tools like saws and shearing. They might not be as fancy as lasers and may even lack precision, but they are cost-effective and get the job done nonetheless for simpler cuts and certain materials.

Laser Cutting is awesome for making detailed stuff like small parts for gadgets or doing fancy designs in metal. Plus, it doesn’t waste much material.

Plasma Cutting is perfect for cutting thick metal plates like for building things. It’s pretty quick and good for simpler shapes.

Water Jet Cutting method can handle different materials without the need for heat. It’s used in things like making parts for airplanes or creating artistic metal pieces.

Traditional Methods and cutting tools work well for simple jobs or thicker metals where precision isn’t as important. They’re usually cheaper too.

When picking how to cut your metal, think about

Ready to Get Your Metal Project Started?

MIG welding uses a wire electrode fed through a welding gun, where it melts to join the metal pieces together. It’s popular for its ease of use, making it great for beginners and for welding thin to medium-thick metals.

TIG welding involves using a non-consumable tungsten electrode to create a precise weld. It’s known for its high-quality welds ideal for critical applications, and works well on a variety of metals.

Arc welding uses an electric arc between an electrode and the base material to melt and fuse metals. It’s versatile applicable to various metals and thicknesses making it a common choice for construction and fabrication.

Spot welding joins metal surfaces by applying pressure and heat to specific spots. It’s fast and efficient for joining thin metals in automotive and sheet metal industries

MIG Welding offers quick welds and good versatility. However it may create heat-affected zones and is limited in welding thicker materials.

TIG Welding provides precise and clean welds suitable for high-quality projects but is slower compared to other methods and requires more skill.

Arc Welding is versatile and powerful used for different metals and thicknesses but it may result in splatter and distortion and it requires a steady hand for consistent welds.

Spot Welding is rapid and cost-effective for thin metals, yet it’s limited in versatility for thicker materials and may require additional finishing work.

Several factors influence the selection of a welding technique:

Forming, also commonly referred to as bending, involves deforming metal by applying force to create curves or angles. It’s used to shape metals into various forms without breaking or compromising structural integrity.

Stamping presses metal into specific shapes using dies and punches. It’s efficient for mass production of consistent parts and intricate designs.

Rolling involves passing metal rolling to reduce thickness or create uniform shapes. It’s used in manufacturing sheets, tubes, and structural components.

Forging shapes metal by applying compressive force through hammering or pressing. It enhances metal strength and is used for producing sturdy and durable components.

Bending is applied in manufacturing brackets frames and architectural components. Benefits include creating curves without weakening the metal’s structure and allowing versatility in design.

Stamping is used for making car parts, appliance components, and metal ornaments. Benefits include high-speed production accuracy and repeatability of parts.

Rolling is utilized in producing sheets for construction, automotive and aerospace industries. Benefits include consistent thickness, improved material properties and cost-effectiveness.

Forging is applied in producing tools machine parts and high-strength components. Benefits include improved material strength, grain structure refinement and enhanced durability.

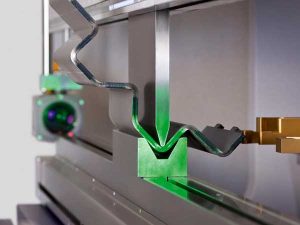

Laser welding offers superior precision and accuracy, minimal heat-affected zones, and versatility in material compatibility. These factors contribute to its advantage over traditional welding methods.

Welcome to Superior Metal work your trusted partner for top-tier custom metal fabrication services tailored to your unique needs. With

At Superior Metal Work LLC we take pride in providing high-quality metal fabrication solutions that cater to the diverse needs

From the towering skyscrapers that define city skylines to the complex machinery powering our everyday lives metal fabrication is used

Copyright © 2025. Superior Metal Works LLC All rights Reserved.

“Designed & Developed by American Web Designers“